Imagine a world where we looked at used consumer waste as a new resource, something that can make practical and even stylish products to be used every day, again. This is exactly how Zephyr has begun to look at possible materials available to make our sunglasses.

Zephyr born in 1994 has a long and rich history in crafting practical and on trend sunglasses. The team spends a large proportion of their time researching new manufacturing processes, finishes and the latest in eyewear tech to wrap them up into value price point eyewear that represents real value.

There has been significant investment and research into renewable and sustainable options in manufacturing sunglasses that not only meet the Australian and New Zealand standard 100% UV protection, but also use materials that will contribute to reducing waste and give a new life to plastics primarily that are here on earth to stay.

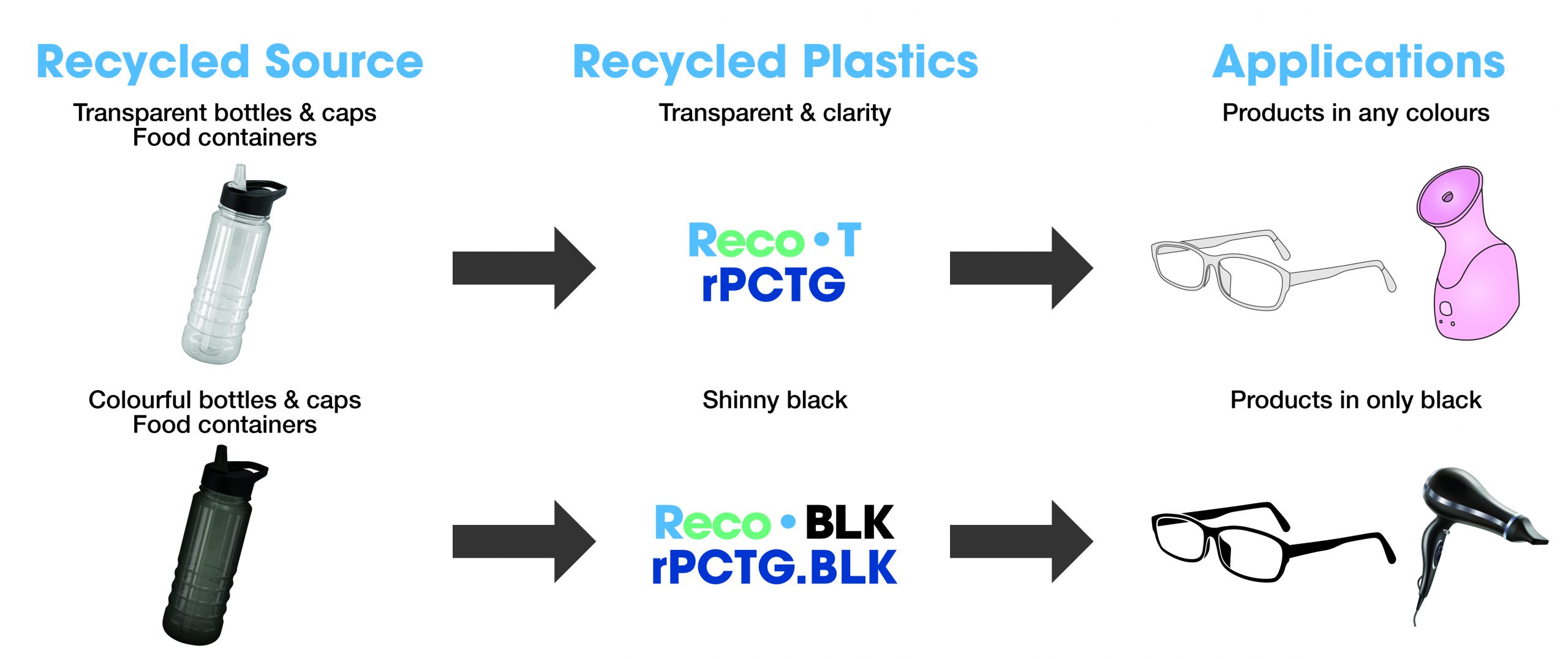

The latest feature in the 700 plus strong SKU collection is an Eco Range made from recycled sourced material called “rPCTG”. In short transparent or coloured food containers, bottles or caps are crushed and washed then reprocessed into primary materials to make new products. This process does not impact the integrity of the base material, just creates a new perfect primary material to make the product from. Keep an eye out in store for the “Eco-friendly” Logo and the amazing styles that have been crafted from this material.

Zephyr is keen to invest in more research to see what other environmentally friendly materials can be used to increase the sustainability of our product and business even further. Durability and quality will be the determining factor to ensure the product meets the high standards everyone has grown to love about the product. For now the Eco range has arrived, so here is to enjoying the sun, and looking after our beautiful planet into the future.